New Zealand Wool: Naturally Durable and High-Quality Fiber

New Zealand is renowned for its breathtaking landscapes, which are vast and beautiful enough to be featured as filming locations in major films. This expansive nature also provides ideal conditions for sheep, allowing them to graze freely and grow robust, high-quality wool without stress.

In Queenstown, located on the southern part of New Zealand’s South Island, sheep endure extreme conditions, with temperatures rising above 30°C in summer and dropping to -20°C in winter. To survive these temperature fluctuations, New Zealand sheep have wool with a unique crimped structure, known as crimp, which traps insulating layers of air, protecting them from external temperatures. This structure not only helps the sheep but also results in wool that’s perfect for creating warm, insulating knitwear.

The Benefits of New Zealand’s Climate and Animal-Friendly Practices

The significant temperature variation in New Zealand has an additional benefit. In some countries, a practice called mulesing is performed to prevent parasite infestations in sheep. However, New Zealand’s harsh climate naturally limits the presence of these parasites, eliminating the need for such practices and allowing for cruelty-free wool production. Mulesing is even prohibited by law in New Zealand, making this wool more ethical and animal-friendly.

Auctioning and Quality Assessment of New Zealand Wool

After shearing, New Zealand wool goes to auction. New Zealand and Australia are major wool producers globally, and raw wool from these countries is gathered in Australia, where wool buyers from around the world assess it. Wool is graded by quality, with some buyers basing their decisions solely on numerical data. However, we work with wool buyers who personally evaluate the raw wool for factors like strength and fineness, ensuring the final product retains exceptional softness and quality.

From Raw Wool to Yarn: The Production Process

After purchasing, the wool is shipped to China for spinning. Initially, the wool undergoes scouring to clean it of impurities. The clean wool is then carded, forming rope-like bundles called tops. Dyeing at the top stage creates a mélange effect, as various colors are blended before spinning. Next, the tops are drawn out through a process called full spinning and twisted to create yarn.

First, the wool that has just been sheared on the farm is dirty, so it goes through a process called "washing" to wash it.

Once the hair is cleaned, the individual fibres are separated and made into rope-like bundles called cards.

The fabric is then stretched using a comb with fine needles, and when wound up it becomes the "top" which is the raw material for thread.

Dyeing the top at this stage allows various colors to be combined to create yarn, creating the melange look that is unique to tops.

After that, it moves to a process called full spinning, where it is stretched thinly from the top, and then twisted to finally become thread.

Our Unique Yarns

At our knitwear factory, we work with two types of yarn:

Woollen Yarn (Bōmōshi): This thick, lightly twisted yarn emphasizes the natural softness of wool. Our original yarn blends 17.5-micron New Zealand wool with cashmere from Inner Mongolia. Typically, wool measures around 19–24 microns, while cashmere is around 14–16 microns. The finer the yarn (lower microns), the softer and less prickly it feels. For comparison, human hair is about 70–80 microns thick. Unlike top dyeing, yarn dyeing allows for smaller dye lots, minimizing surplus stock and waste.

Worsted Yarn (Somōshi): This fine yarn is developed using a combination of compact spinning and Sirospun techniques, giving it a slight sheen and a smoother finish. The unique method wraps fibers into the yarn, making it both lustrous and easier to care for.

Experience the softness and quality of QUEENSTOWN WOOL, crafted from the finest New Zealand wool and made with a focus on sustainability and exceptional quality.

Click here for ANNUAL products made with QUEENSTOWN WOOL.

(Transition to external site)

NEWS

MNインターファッション株式会社、ベトナムの国際繊維展示会「VIATT」に出展~自社素材ブランドを通じ、アパレル・寝装寝具分野でのOEM提案を強化しグローバル市場へ~

MNインターファッション株式会社は、ベトナム・ホーチミンにて開催される国際繊維・アパレル展示会「VIATT(Vietnam International Apparel, Textile and Textile Technologies Exhibition)」に出展いたします。 本展示会では、当社が展開する自社素材ブランド「WA.CLOTH」「BANANA CLOTH」「AERO...

Read more

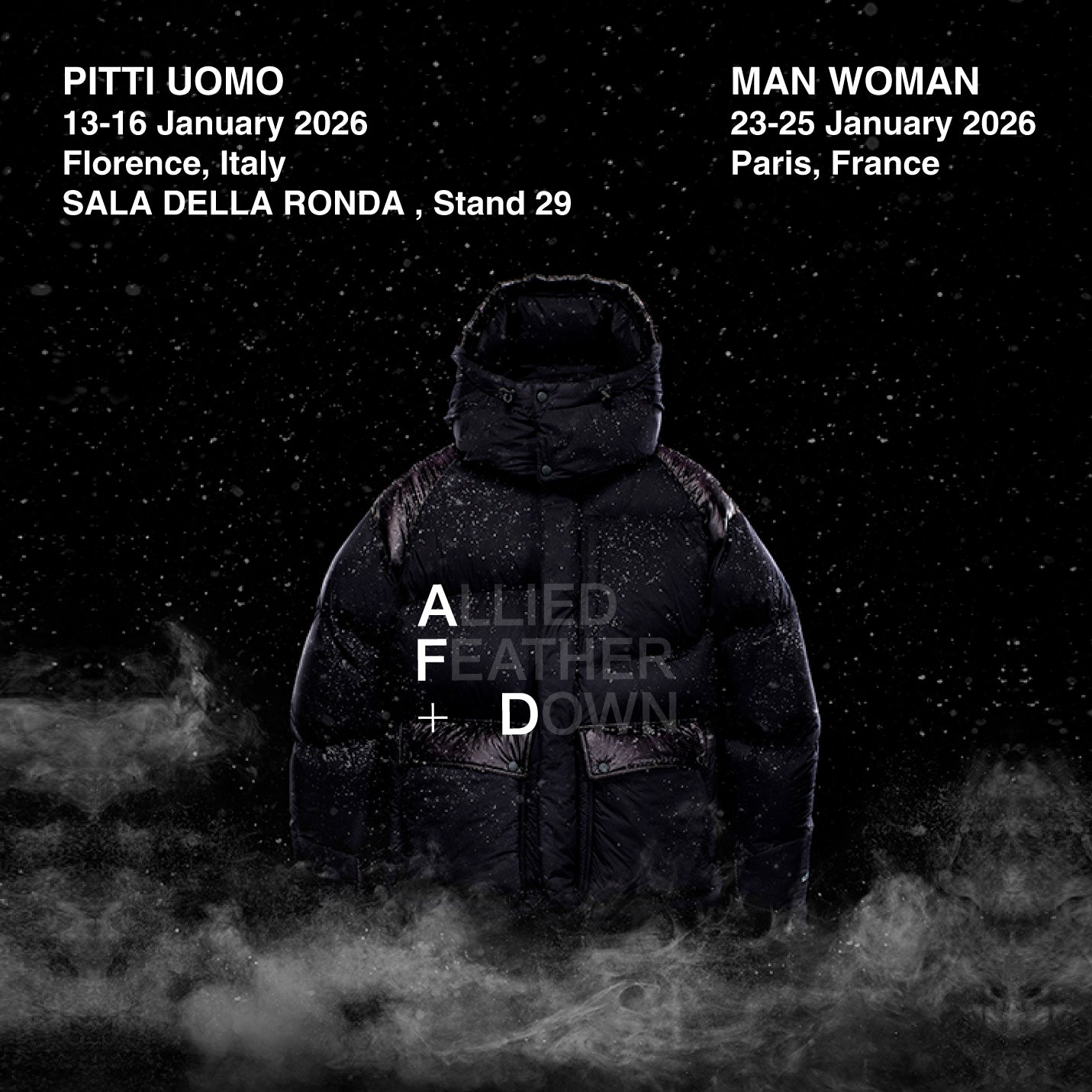

ALLIED FEATHER + DOWN、Pitti Uomo AW出展を盛況のうちに終了 MAN/WOMAN AWへの出展も決定、欧州主要展示会での挑戦を継続

MNインターファッション株式会社が展開するダウンブランド「ALLIED FEATHER + DOWN(アライド・フェザー・アンド・ダウン)」は、2026年1月13日(火)から16日(金)までイタリア・フィレンツェで開催された世界最大級のメンズファッション展示会「Pitti Immagine Uomo」に出展し、盛況のうちに終了いたしました。 また、同ブランドは、2026年1月2...

Read more

MNインターファッション株式会社、三井物産フォレストとの協力による植樹活動が5年目へ― 今年度は北海道十勝にて2,000本を植樹、累計14,000本の植樹を実施 ―

MNインターファッション株式会社は、三井物産フォレスト株式会社および三井物産株式会社との協力のもと、三井物産が保有する山林における植樹活動を継続して実施しており、本年度で5年目を迎えました。今年度は、新たに2,000本の苗木を植樹し、本取り組みを通じてこれまでに累計14,000本の植樹を行ってまいりました。 ■ 持続可能な未来への取り組み 当社は、ファッション素材の開発と製品づくり...

Read more